In recent years, the oil and gas industry has seen significant advancements in deep offshore technology. As the demand for oil and gas continues to grow, companies are pushing the boundaries of exploration and extraction to reach deeper reservoirs. This evolution in deep offshore technology has not only transformed the way we extract natural resources but has also led to increased efficiency, safety, and environmental sustainability. In this article, we will explore the evolution of deep offshore technology and how it is shaping the future of the oil and gas industry.

The Early Days of Deep Offshore Technology

The concept of deep offshore technology dates back to the early 20th century, when companies began exploring beyond shallow water reserves. As technology evolved, so did our ability to extract resources from greater depths. In the 1970s, projects like the Ekofisk field in the North Sea marked a turning point in deep offshore technology, demonstrating the feasibility of drilling in harsh environments.

Key Advancements in Deep Offshore Technology

Over the years, significant advancements have been made in deep offshore technology to overcome the challenges presented by deepwater drilling. Some key advancements include:

- Subsea Production Systems: Subsea production systems have revolutionized deep offshore technology by allowing companies to produce oil and gas without the need for traditional surface facilities. This technology enables companies to access remote and deepwater reservoirs while minimizing environmental impact.

- Floating Production Storage and Offloading (FPSO) Vessels: FPSO vessels are another essential advancement in deep offshore technology, providing a cost-effective solution for processing and storing oil and gas offshore. These vessels can be deployed in a variety of water depths and are easily repositioned to maximize production efficiency.

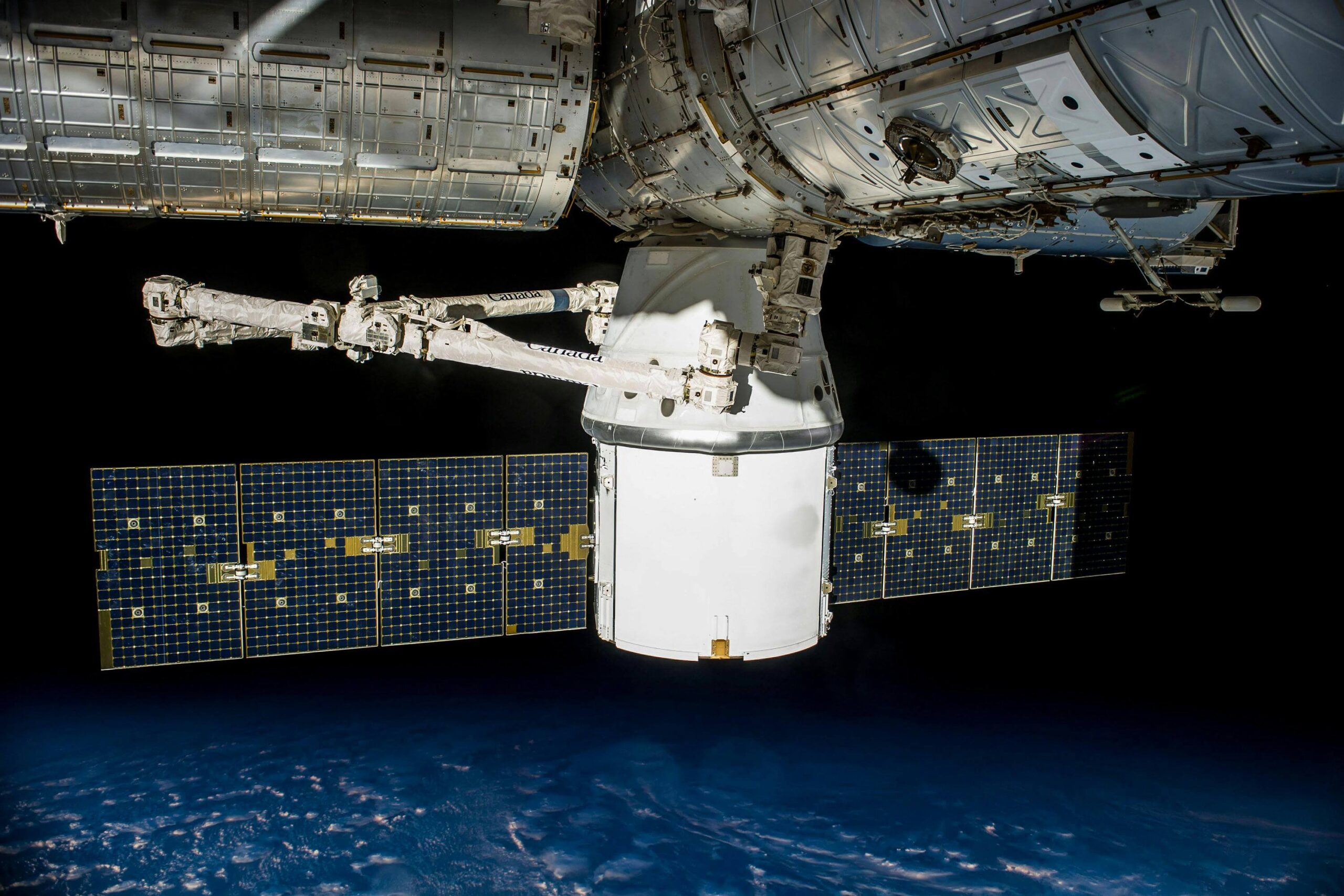

- Remote Operating Vehicles (ROVs):ROVs have become essential tools in deep offshore technology, allowing companies to perform complex operations at depths that are unreachable by divers. These remotely operated vehicles are equipped with cameras, sensors, and robotic arms to perform tasks such as health maintenance, pipeline inspection, and subsea construction.

- Advanced Drilling Technology:Advances in drilling technology, such as managed pressure drilling and enhanced leak detection systems, have improved the efficiency and safety of deep offshore operations. These technologies allow companies to drill deeper wells with greater precision and control, reducing the risk of blowouts and spills.

Exploring the critical components of deep offshore drilling technology

Deep offshore drilling technology involves a sophisticated system of equipment and processes that allow for the extraction of oil and natural gas from deep beneath the ocean floor. The key components of this technology include highly specialized drilling rigs, blowout preventers, subsea wellheads, and remotely operated vehicles. These components work together seamlessly to allow for safe and efficient drilling operations in challenging deepwater environments.

One of the most important aspects of deep offshore technology is the use of advanced drilling rigs, such as dynamically positioned drillships or semi-submersibles. These rigs are equipped with state-of-the-art drilling equipment, including blowout preventers that are designed to control and contain any unexpected healthy pressure. Additionally, subsea wellheads are installed at the seabed to provide a connection point for the drilling operation, allowing for the extraction of resources from deep beneath the ocean floor.

The role of robotics and automation in deep offshore exploration.

Robotics and automation play a crucial role in the deep offshore exploration sector by increasing efficiency, reducing human risk, and enhancing data collection. With advancements in deep offshore technology, robotic systems are able to perform complex tasks such as drilling, maintenance, and data gathering in extreme environments where human intervention is challenging. These robots are equipped with sensors and cameras that help them navigate through underwater terrains and collect valuable information for analysis.

One of the key advantages of utilizing robotics and automation in deep offshore exploration is the ability to operate 24/7 without the need for breaks or rest. This continuous operation ensures that data collection is consistent and accurate, leading to better decision-making and resource allocation. Additionally, robotics can access areas that are difficult for humans to reach, enabling exploration in deeper and more remote locations that were previously unexplored.

The Future of Deep Offshore Technology

As we move forward into the future, deep offshore technology is expected to play an increasingly important role in the exploration and exploitation of oil and gas resources. One of the key trends that we can expect to see is the continued development of advanced drilling techniques and equipment that will allow for exploration and production in even deeper waters. This will not only enable access to previously untapped reservoirs but also improve efficiency and reduce costs in the long run.

Another important prediction for the future of deep offshore technology is the increased use of autonomous systems and robotics. As the industry moves towards more remote and challenging environments, there will be a growing need for technology that can operate independently and efficiently without human intervention. This will not only improve safety by reducing the need for personnel to be on-site but also allow for more precise and controlled operations in complex underwater environments.

As we look to the future, the evolution of deep offshore technology is set to continue with further advancements in automation, digitalization, and sustainable practices. Companies are exploring new ways to optimize operations, reduce costs, and minimize environmental impact through innovation and collaboration.

Automation: Automation is poised to play a significant role in the future of deep offshore technology, with companies investing in autonomous systems for drilling, production, and maintenance. These systems can improve efficiency, safety, and reliability by reducing human error and increasing operational control.

Digitalization: The oil and gas industry is increasingly embracing digital technologies to optimize deep offshore operations. By leveraging data analytics, artificial intelligence, and machine learning, companies can improve decision-making, predict equipment failures, and optimize production efficiency.

Sustainability: With growing concerns about climate change and environmental impact, companies are prioritizing sustainability in their deep offshore operations. This includes implementing technologies to reduce carbon emissions, minimize waste, and protect marine ecosystems. From green completions to carbon capture and storage, the industry is committed to reducing its environmental footprint. view here for more info

Conclusion

The evolution of deep offshore technology has transformed the oil and gas industry, allowing companies to reach new depths and extract resources with greater efficiency, safety, and sustainability. From subsea production systems to automation and digitalization, advancements in deep offshore technology are revolutionizing how we explore and produce natural resources. As we look to the future, continued innovation and collaboration will be vital to unlocking the full potential of deep offshore technology and shaping the future of the industry.